The 30 AFW Teflon Wire is a lead wire that is engineered to operate in the harshest and most extreme industrial conditions. ZW Cable has designed the most robust and high-quality hook up Teflon wires on the market. Our Teflon Wires can withstand high temperatures, frequencies, and various elements. Our expert team of engineers has designed & engineered our wires for maximum endurance even in the most challenging conditions. This guide will focus on the basics of PTFE Hook Up wire, the benefits, protective coating, and other essential information.

What Does PTFE Stand For?

The 30 AWG Teflon Wire, also known as 'PTFE' or 'lead hook up wire' is a wire that can withstand extremely high temperatures for electronic applications. The wire is coated in Polytetrafluoroethylene (PTFE) insulation that can handle exposure to harsh elements such as chemicals, oils, solvents, and different forms of abrasion. Depending on the wire, many of them can handle higher moisture exposure and flame. Our wires are capable of enduring exposure to flame, oils/gas, thermal aging, and more.

We produce our Teflon Wires uniform to enable fast processing for industrial use including easy stripping. The protective material we use called PTFE is a fluorocarbon polymer which enables wiring systems to be used in extremely challenging environments. Our PTFE wires can resist the widest range of oils/fuels, flame, lubricants, chemicals. They also retain high thermal and electric properties. If the job requires high resistance to temperature and chemicals, our wires will get the job done!

The following is a list of the top benefits of Teflon Wires for industrial use:

✔ Extreme temperature resistance from -60°C (-76°F) up to 200°C (392°F).

✔ High voltage options ranging from 250V up to 1000V.

✔ Resistance to chemicals, oil, gas, flame, and more.

✔ High bend radius, making them easy to customize and install in any environment.

✔ Can be purchased in large lengths such as 1000 ft.+.

✔ Copper-made conductors are available in stranded or silver-plated options.

✔ Lesser radius and lower weight compared to other insulation wires such as PVC.

Pragmatic Uses For Teflon Wire

The primary use for Teflon Wire is in the industrial and military spheres. The most common use is military harnessing and they serve as lead wires for the power supply of large industrial buildings. The wires can also be used for wiring different appliances and electronics - they're very common in the medical field. Generally, hook up wires are essential for all applications where you encounter high temperatures.

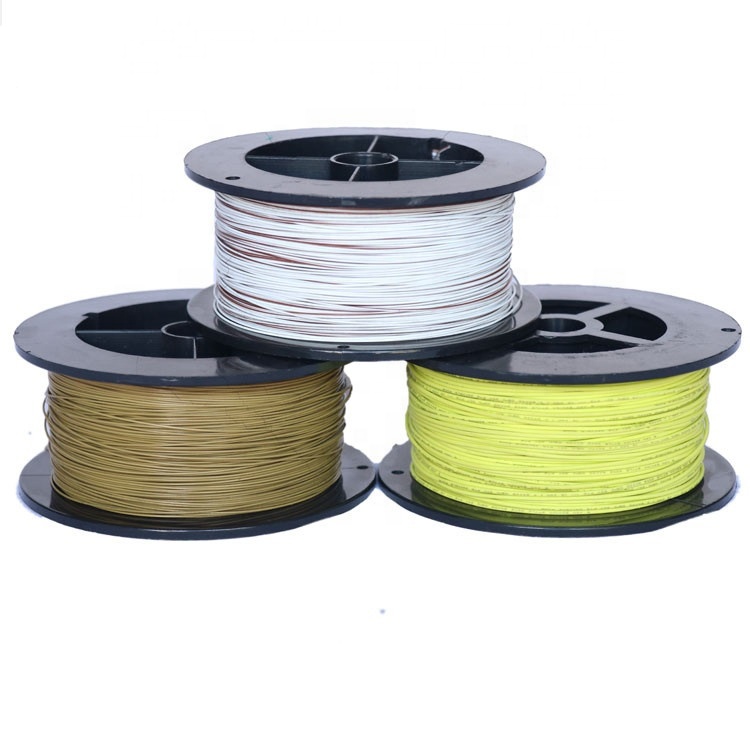

Due to high resistance to the elements and high-powered electrical properties, PTFE wires have found their way to industries such as aerospace, military-industrial, medical, and other commercial markets. Teflon Wires are available in a diverse range of colors such as black, blue, red, white, green, and yellow in order to make it easier to differentiate them when in use.

PTFE Insulation Benefits

The main advantage Teflon Wires offer over regular wires is the PTFE insulation. PTFE insulation gives wires much higher resistance to the elements which makes them the most stable wires in any wiring system. This provides a high degree of reliability in sensitive environments where you want to eliminate the risk of failure.

Teflon Wires are also resistant when it comes to UV radiation, chemicals, oils, stress/pressure, molding, and other forms of damage. PTFE material means they're also built using non-toxic materials, which reduces the risk it poses on humans. PTFE coating makes it easy to flex the wires, and it allows owners to conserve space and weight compared to other insulation types. This type of wire is generally easy to install.

Teflon Wire NEMA Types: 3 Types

According to the National Electronics Manufacturers Association (NEMA), an organization that sets the standards for electrical enclosures in North America, there are 3 main types of Teflon Wires: E, EE, and ET. Each one of these is designed to provide protection against potentially hazardous conditions, and you should make your decision based on the intended use of the wire. The following is a breakdown of the 3 main types:

1) E Teflon Wire: The type "E" Teflon Wire is used for industrial applications with high temperatures. E type is suitable for a maximum of 600V or high-frequency circuits.

2) EE Teflon Wire: The EE type is also intended for high-temperature industrial use and usable for a maximum of 1000V or high-frequency circuits.

3) ET Teflon Wire: ET type is the most wide-spread and designed for use in high temperatures with low voltage. ET Teflon Wires are suitable for a maximum of 250V or high-frequency circuits. Note: ET wires can be more fragile than E and EE wires meaning you should only use them in a low-risk environment where they're not exposed to high mechanical pressure.

Teflon Wires can have varying rated voltage. This is one of the main factors to consider when you purchase hookup wires. The voltage can affect the design when it comes to the thickness of the insulation. Most Teflon Wires that can support high voltage such as E and EE type have thicker insulation.

· In terms of energy consumption, wires that use less than 1 kV are considered "low voltage" while views that use more than 36 kV are considered "high voltage". The most popular Teflon/hook up wires are low voltage.

How does the insulation quality of the 30 AWG Teflon Wire compare to other popular insulation types such as neoprene and PVC? The insulation in industrial wires is called a jacket and it’s designed to prevent electric leaks away from the conductor. The most effective insulation is thermoplastic insulation - Teflon Wires belong to this category along with Tefzel, Polyethylene and PVC wires.

The main alternative to thermoplastic wires is silicon rubber which is more flexible; however, it lacks the rigidness and chemical resistance of thermoplastic-insulated wires. Neoprene is also a popular material made of synthetic rubber which can be used for industrial chemical applications due to resistance to oil and flames. To summarize: Teflon Wires are the most resistant wires on the market, and they provide other advantages such as flexibility.