The future of solar power transmission mediums is here. Commercial, Industrial and other establishments must either embrace it…or be left behind! That’s the message that everyone, from climate activists to sustainable corporate operation specialists and politicians, is sending out across the world. The future of power generation is going to be markedly different than what it is today, with solar power already playing a key part in shaping that future. And a key component in that future is the solar cable, without which one can’t imagine the viability of solar-powered technology.

The benefits of using solar transmission mediums

Let’s face it: The world is becoming more environmentally conscious than ever before in the history of mankind. Analysts predict that by the end of the current decade, an overwhelming amount of our power consumption will come through solar power. As a result, demand for solar wire, and related solar power transmission mediums and components will rise dramatically.

So, why are individuals, groups and nations gravitating towards solar energy? The answer is:

It’s “clean” – meaning there’s major carbon emissions associated with it

It’s energy efficient – and that means solar power delivers greater amounts of energy than traditional generation projects

It’s environmentally friendly – which means that, unlike traditional transmission projects, solar energy projects produce less Greenhouse Gasses (GHGs)

It’s sustainable – which means that so long as the sun shines, which, by some expectations is millions of years more! – the world can sustain solar projects

For these reasons, as the popularity of solar-powered projects grow, solar cable demand will correspondingly increase. And that increase will add to yet another benefit for moving towards solar power: Cost!

Cost, for any commodity or component, is a function of demand. The greater demand is for something, manufacturers and suppliers produce more of it. And, as production increases, as predicted for the case of solar wire in the coming years, the cost of it will decline. And we are already seeing that trend in action. Just a decade or so ago, solar transmission technology was extremely cost-prohibitive. However, today those costs have declined to such an extent that solar power projects are more economical today than they were a few years ago.

The benefits of low-cost solar transmission mediums have another impact globally. For example, Denmark has more than doubled its solar and wind power generation capacity over a 10-year period. That’s largely thanks to the declining costs of such transmission, so more individuals and families can connect to power grids – many of them for the very first time in their lives. And the key to accomplishing that level of prosperity is the power that the solar cable unleashes for humanity.

Generally-speaking, your choice of the cable you use will determine the quality of your power generation and transmitting solution. While wiring of a slightly less than optimal specification might keep your application running for the short duration, in the long-term, it may compromise efficiency and productivity of the entire system. So, what characteristics in a solar wire should you be looking for when deciding the medium to use for your solar power transmittal application?

Well, before we explain the critical elements of the desired specification, lets understand the what’s at stake.

If you use under-specked (thinner gauge) solar cabling, you’ll likely experience excessive loss of power due to a significant drop in voltage. Also, undersized wiring poses a significant fire risk because of heating during the power transmittal process. Electrical engineers always advise that, when choosing a solar cable for specific applications, designers of power solutions must keep these two factors front and center.

Then, there’s diameter of the cable to consider. Just like a large-diameter water pipe doesn’t restrict the smooth flow of water, so too is the case with large diameter power cables. In general, though this may vary as a result of specific applications, the thicker the cable the less resistance power flowing through it faces.

This general principle also applies to the length of the solar wire used. Because of the distance (length) that the power must travel in them, longer cables offer more resistance than shorter ones. If an engineer specks a project with unnecessarily longer cables, or if project designers use smaller (thinner) gauge cables, the power transmitting capacity of the project gets compromised. In either/both cases, fewer than planned watts of power travel to the battery, power bank, power grid or the end consumption point (home, business or factory).

Clearly, your choice of an appropriate solar cable makes all the difference to the efficiency of your power project. Both over and under specked wires are unacceptable. They’ll both cause significant losses (both in terms of monetary and power transmittal) and, in some cases, result in safety concerns, including fires, power outages and damages to plant and equipment.

Whether it’s a PV power project that stores solar power for later use, or whether it’s an application to directly run a piece of plant or equipment using solar power instead of power from the grid generated from fossil fuels, which solar wire you use makes a difference. Here are some best practices to help you as part of power cable evaluation and selection process:

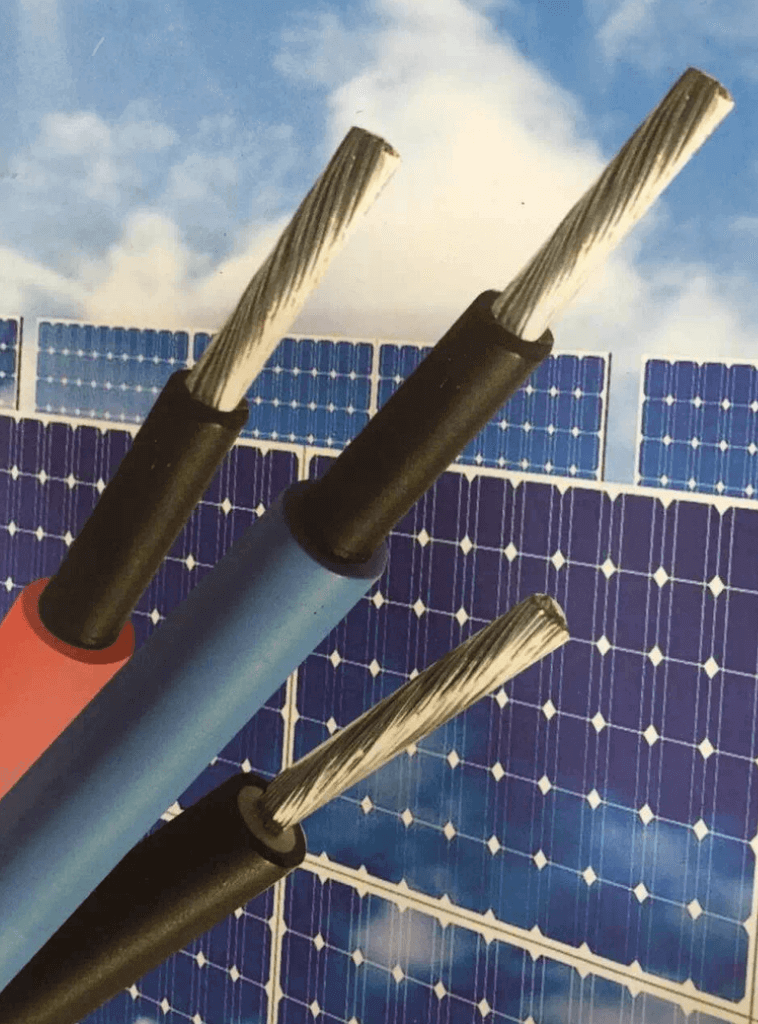

1)Consider the application: The typical tinned copper cable comes in various specks, from 4.0mm to 6.0mm and 16.0mm, zero halogen polyolefin compound cables and cross-linked polyolefin compound wires. When putting your project design together, make sure you understand what your application is all about, and then choose the most appropriate solar cable for that application

2)Consider the weather: Regardless of what the application is meant for, the weather plays a significant part in deciding how to speck the power cables used to support the project. However, both application and weather typically factor together for the purpose of choosing the most appropriate wiring for a project. Usually, for 20,000 hours of operation, the maximum conductor temperature of the selected solar wire should rate at approximately 120o C, and a minimum rating of -40 o C

3)Consider the desired voltage ratings: There are varying applications for solar power cables and wires. Not all applications require equally rated power cables. So, depending on the unique needs of each of those applications, designers determine the appropriate voltage rating for the selected cables. Typically, for 5-minute duration, the acceptable voltage ratings are 1.5 (1.8) KV DC / 0.6/1.0 (1.2) KV AC, high-6.5 KV DC. Make sure your cable choice factors that information into the decision

4)Account for the application environment: We talked about the weather conditions that solar power cables must operate in. However, sometimes project designers face more than heat and cold environments when routing their solar cable from one point to another. Regardless of the environment being an indoor or outdoors application, you might have to speck your cables to deal with acids, alkaline chemicals or mineral oils. Make sure the cables you choose are resistant to such environmental factors.

5)Make allowances of installation requirements: Some solar power projects are simple. Others have unique installation challenges depending on the application and internal and external factors. A solar wire specked for one type of installation process might not be conducive for an installation with different steps or requirements. Some installs require a specific pulling force. Others might involve greater degrees of stress or impact during installation.

When deciding which type of cable to use, make sure you consider factors such as impact resistance, tear and abrasion. For best installs, the bending radius of your solar cable must not exceed four-times that of the cable’s overall diameter. A safe measure of the cable’s pulling force is –50 N/sqmm.

6).Insulation considerations: Insulation and casing is a key consideration when deciding which solar wire or cable to choose. Of course, the type of insulation will likely depend on each unique set of installation and application. As a general best practice, the insulation must have the capacity to endure mechanical and thermal loads of the project. That’s why cross-linked plastics are becoming the go-to insulation for outdoors, indoors and heavy-duty solar power applications.

Flame-resistant, cross-linked, halogen-free jackets are another popular choice. Best practice principles suggest them for use in projects exposed to salt-water, high-acidity and corrosive environments. Additionally, these cables are ideal for indoor applications too, especially in dry conditions. The rugged insulation makes them more fire-resistant and less prone to damage and degradation.

Recapping the best practices for selecting the ideal solar cable - weather-proofing, UV-resistance, wide-ranging temperature (120o C to -40 o C), stress-proof, abrasion-resistant, flame and fire-resistant, appropriate diameter and length – are characteristics to consider when solar power project designers decide on which types of solar cable to use. And staying within the boundaries of those best practices, it is imperative that the supplier of your cables and wires delivers to these high standards.

Here, at ZW Cable, we are a solar wire manufacturer who not only meets those best practice standards, but exceeds them by a wide margin. Our depth of wire and cable manufacturing experience, and the variety of products we offer – from electrical wire, trailer wire and battery cables, to solar cables, welding cables and high-temp cables – makes us the best of breed choice and the number one go-to provider of solar transmission mediums in the industry.