We are mosting likely to need to take a back-to-basics method. The very first thing to take on is the modest electrical wire. Exactly how do they function, anyhow?

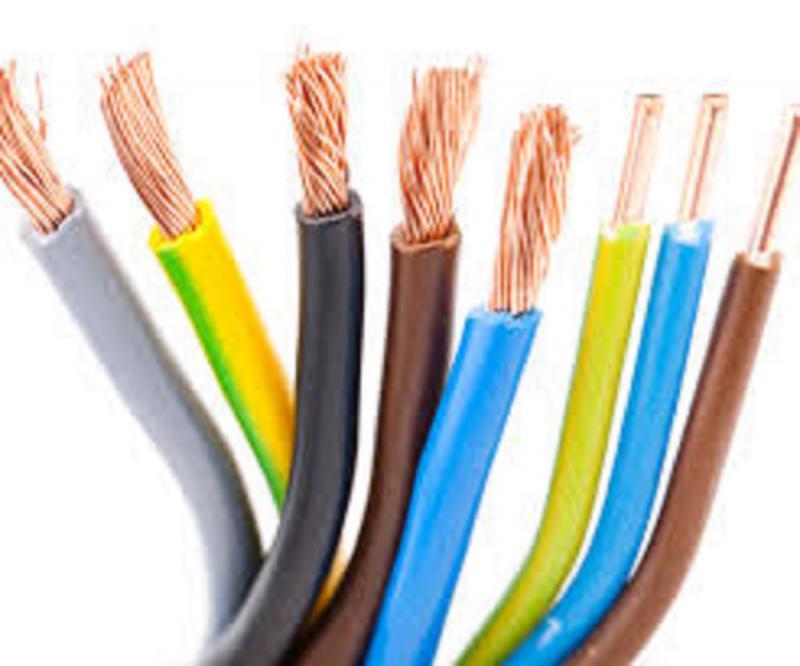

Flexible electrical wire connect our electrical tools as well as devices to a power source, creating a "bridge" for the present to go through. This is done by the use high conductivity products such as copper, aluminum, or stainless steel. Many electrical wires televisions made use of for indoor wiring, which are most likely the most acquainted to us, are ZW Cable. ZW Cable is made of three or more wires wrapped inside an adaptable plastic coa

There are also various other sorts of flexible electrical cable that are used for more customized applications. ZW wires are created for applications that call for the link of numerous parallel wires but are restricted to low-level voltages. On the other hand, protected wires are encased by hairs of conductive product to decrease electro-magnetic disturbance and are normally for sensitive or high-voltage applications.

Despite the relatively easy principle behind their usage, there are loads of various sorts of electrical cords and also selecting which one is ideal for your usage can be a little bit overwhelming. This can be made much easier by comprehending exactly how each feature of the electrical cord influences its efficiency.

In flexibe electrical wires, size refers to the diameter of the metal conductor. These are commonly offered according to the American Wire Scale (AWG) system. Little AWG numbers are assigned to bigger size wires and are likewise an indirect step of just how much current can travel through the cable safely. A 10-gauge cable can just safely transfer a 30-amp existing while a much thicker 2-gauge can take care of up to 95 amps. There is a high danger for a brief circuit or warmth accumulation when the size of a cord is not appropriately matched to the amperage of the circuit for to which it will be used for.

2. Flexible Electrical Wire's Conductor

A conductor is any type of material that permits current to go through as well as is a crucial component of all sorts of cables. A large bulk of all electric cables used today make use of copper as their conductor product Although copper is by no implies one of the most conductive metal, it additionally features the desirable attributes of being economical as well as pliable as well as having high warmth resistance. This has made it very easy to style long and also versatile cords from copper.

In the past, aluminum was virtually similarly as popular as copper as a product for electrical cable. Nonetheless, the method of aluminum slowly discolored as it became apparent that it was not as conductive as copper and was additionally a lot more prone to sneaking when overheated. The growth and also tightening of light weight aluminum cables as they repetitively underwent cycles of heating & cooling led to incurable links coming loose.

Silver and gold are likewise very conductive steels, however they are just appropriate for extremely specific circuitry applications. Gold, besides being very costly, is also extremely flexible, making it the liked conductor microprocessors and motherboard. Silver is a lot more conductive than copper however is moderately used because it is chemically an extremely reactive steel.

3. Flexible Electrical Wire Insulation

Flexible Electrical Wire within a solitary wire need to be covered with insulation to avoid entering into call with each other and creating a short circuit. The wire itself is likewise covered with a protecting jacket to protect the wire versus outside damages and to lower electric leak.

When selecting for the very best material for wire insulation, the quality of the material and how it reacts to the environment needs to be thought about. Some materials might have exceptional warmth resistance, while others can preserve their versatility also in severe cold. For cables in exterior applications, the shielding product has to have a high degree of UV resistance. Some applications might call for that the wires be able to move around regularly, so the protecting product has to not end up being fragile or stiff over time.

The selection of which shielding product to make use of for a cable is most likely among one of the most complicated choices to make when making a circuitry installation, so for the fact that there many choices. There are easily-accessible plastic options such as PVC, PE, or Nylon. There are additionally rubber items that all offer the benefit of adaptability, such as Silicone or Neoprene. While all these products generally do a good task of avoiding contact between cables, they differ in longevity and also longevity relying on the environment.

Flexible Electrical Wire link our electric gadgets as well as appliances to a power source, developing a "bridge" for the existing to pass through. There are likewise various other kinds of electric wires that are utilized for even more specific applications. Bow wires are made for applications that require the link of a number of parallel wires yet are restricted to low-level voltages. Tiny AWG numbers are assigned to larger diameter wires and also are additionally an indirect measure of how much current can pass through the cord securely. In the past, light weight aluminum was nearly similarly as prominent as copper as a material for electrical cables.